Assembly Automation

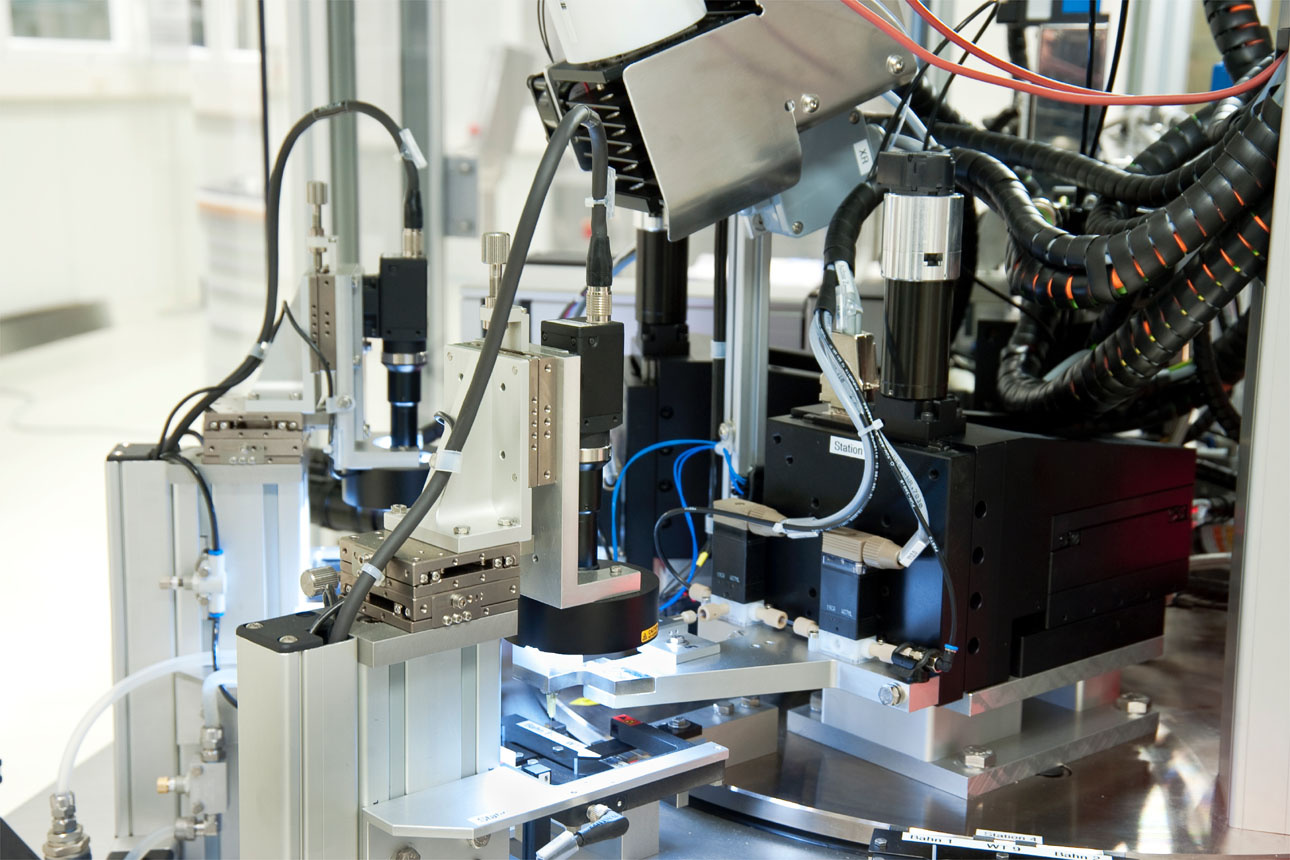

Assembly systems – Assembly automation is our passion and core skill

One of the core skills at SIM Automation is the planning, development and production of individual, customer-specific assembly plants – something we have been involved in for 60 years now. Our product portfolio here ranges from the effective design of individual manual workstations all the way through to completely interlinked, highly automated process lines. In our plants, we handle all common transfer systems and can thus offer solutions that are independent from the branches of our customers, whether medical engineering, pharmaceuticals, food and cosmetics, the automotive industry or electrical engineering.

The advantages of our systems:

Workpiece carrier circulation systems

- Horizontal and vertical workpiece carrier circulation systems, integration of SIM workpiece carrier accelerated in-feed devices and workpiece carrier changing systems

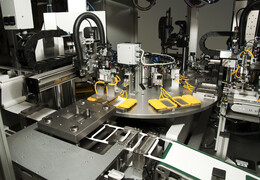

Rotary systems

- Electromechanical drive / pneumatic systems / cam mechanisms

Linear systems

- Electromechanical drive / pneumatic systems / cam mechanisms / loose or direct interlinking

Intelligent manual workstations

- Manual assembly / automated assembly, inspection and testing procedures

Hybrid assembly systems

- Workpiece carrier circulation system linked to manual workstations, automated cells and feeding systems / decentralized and flexible assembly lines / variable expansion through to full automation

One-piece flow / lean production

- Highly flexible assembly concepts for small quantities and small batch sizes for changing product types, high ratio of worker-related work content and responsibility

Contact

Additional systems in assembly systems:

In addition to all standardized joining, measuring, testing and inspection systems, our assembly plants can also implement the customer’s own processes, including:

- Joining, screwing, bonding, riveting, welding (laser, ultrasonic, resistance)

- Testing, measuring, inspecting (optical, tactile, electrical, thermal)

- Robot systems

- Linear systems (pneumatic, electrical, mechanical)

- Cam-controlled drives, linear and handling systems

When it comes to part feeding, SIM has a wide range of own feeding, sorting and palletizing systems to choose from.

Testing and inspection lines we have been involved in:

- Electric high-performance gear components (up to 6 kV)

- Electric central locking systems (vehicles)